—— Cov khoom Center —

Cov khoom

Ceev Fact

Yog tias koj muaj lus nug lossis lus pom zoo, thov nyem lub pob hauv qab no txhawm rau nrhiav lub rooj tsavxwm thiab tawm lus rau peb

Thermoplastic Vibrating Line Marking Xim

Lub sijhawm hloov tshiab: Oct-27-2020

3 Thermo Thermo rau ft koj cov peev nyiaj

Specification ntawm no Thermoplastic Vibrating Line Marking Paint Chaw tsim tshuaj paus

Vibrating thermoplastic txoj kev kos xim muaj cov thermoplastic resin, hloov roj hmab, muab tub lim, thiab cov ntaub ntawv tshwj xeeb thiab lwm yam khoom.Nws yog tsim los ntawm kev ua raws li kev pom kev siab thiab kev co.Nws yog dav siv rau cov kab hauv nruab nrab ntawm txoj kev (hloov-txhim kab), kab ntug ntawm txoj kev loj, hla kab qeeb thiab lwm yam.

Rainy reflections: zoo heev visibility tau txais txiaj ntsig los ntawm kev tsim tshwj xeeb.Txawm tias hmo ntuj los nag, peb tuaj yeem tau txais txiaj ntsig zoo dua.

Nias kab kev vibration: thaum lub tsheb tau tsav kom hla txoj kab-kos npe, nws ua rau lub tsheb me ntsis kev co co tus neeg tsav tsheb kom xyuam xim rau kev nyab xeeb.

Daim ntawv qhia txog vibrating xim

Cov duab ntawm no Tuam Tshoj Thermoplastic Vibrating Line Marking Paint

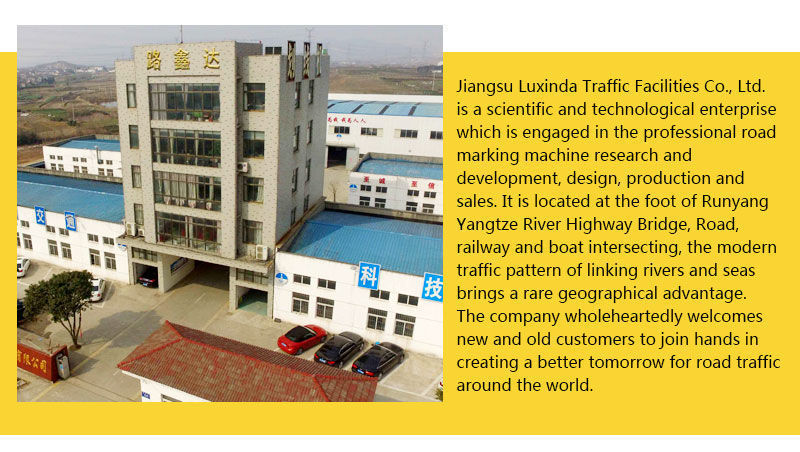

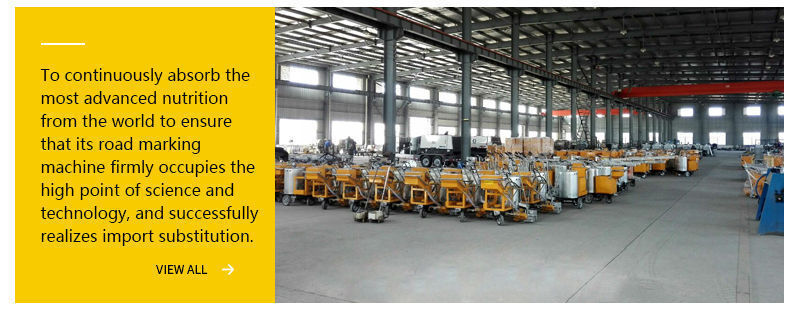

Peb cov duab ntawm no Thermoplastic Vibrating Line Marking Paint Factory

Nrhiav rau pem hauv ntej rau koj qhov kev nug rau no Thermoplastic Vibrating Line Marking Paint Chaw tsim tshuaj paus

Previous nplooj:Tsav tsheb hom kev npav tshuab rau txias yas-Spotline

Cov nplooj ntawv tom ntej:LXD-D168 Tsav Hom Txias Xim Txias Txoj Kev Npav Tshuab

Cov lus qhia ntsig txog

-

LXD-18L High Pressure Airless Cold Paint Spray Road Marking Tshuab

LXD-18L High Pressure Airless Cold Paint Spray ...

-

LXD900 Road Marking Remover

LXD900 Road Marking Remover

-

Ob Lub Cheeb Tsam Rib Kab Txoj Kev Marking Tshuab

Ob Lub Cheeb Tsam Rib Kab Txoj Kev Marking Tshuab

-

LXD860 Self-Propelled Thermoplastic Road Marking Tshuab

LXD860 Self-Propelled Thermoplastic Txoj Kev Markin ...

-

LXD-6L Tes Push High Pressure Airless Cold Paint Road Marking Tshuab

LXD-6L Tes Push High Pressure Airless Txias Pai ...

-

LXD1500 High efficiency txuag hom thermoplastic preheater

LXD1500 Kev ua haujlwm siab zog txuag hom siv ...